In the realm of industrial equipment, side channel vacuum pumps stand out as versatile and efficient solutions for a myriad of applications. With their innovative design and robust performance, they are increasingly becoming the go-to choice for various industries. Let’s delve into the world of vacuum technology and explore the significance of side channel vacuum pumps in particular.

Understanding Vacuum Technology

Before delving into the specifics of side channel vacuum pumps, it’s crucial to grasp the fundamentals of vacuum technology. Vacuum pumps are devices designed to remove gas molecules from a sealed volume, thereby creating a vacuum. This process finds applications across industries such as manufacturing, packaging, and healthcare, among others.

Introducing Dry Vacuum Pump Technology

Among the diverse array of vacuum pumps available, Dry Vacuum Pump have garnered significant attention due to their distinct advantages. Unlike traditional oil-sealed pumps, dry vacuum pumps operate without the need for lubricating oil, making them more environmentally friendly and cost-effective in the long run. Companies like Becker-International have been at the forefront of developing cutting-edge dry vacuum pump technology, offering enhanced reliability and performance.

Exploring Rotary Vane Vacuum Pumps

One of the most widely used types of vacuum pumps is the rotary vane vacuum pump. These pumps employ a rotating vane mechanism to create a vacuum by continuously sweeping gas molecules out of the system. With their compact design and high pumping efficiency, rotary vane vacuum pumps are indispensable in numerous industrial processes, ranging from food packaging to semiconductor manufacturing.

Unveiling the Advantages of Side Channel Vacuum Pumps

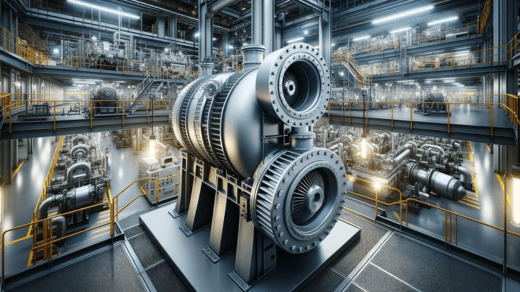

In recent years, side channel vacuum pumps have emerged as a game-changer in vacuum technology. Unlike traditional pumps, which rely on rotating parts, side channel vacuum pumps utilize a unique principle known as the side channel effect to generate vacuum. This innovative design results in a compact, lightweight pump with minimal vibration and noise, making them ideal for applications where space and noise considerations are paramount.

Highlighting the Versatility of Rotary Vacuum Pumps

Another variant of the rotary vacuum pump is the oil vacuum pump, which utilizes oil as a sealing and lubricating medium. While these pumps offer high vacuum levels and robust performance, they also require regular maintenance to replenish and replace the oil. However, advancements in rotary vacuum pump technology have led to the development of oil-free variants, offering the same level of performance without the need for oil lubrication.

Embracing Innovation with Side Channel Blowers

In addition to side channel vacuum pumps, side channel technology has also found applications in the realm of side channel blowers. These devices operate on a similar principle but are designed to generate compressed air or gas instead of vacuum. With their ability to deliver high flow rates and pressures, side channel blowers are indispensable in applications such as aeration, pneumatic conveying, and wastewater treatment.

Applications of Side Channel Vacuum Pumps

The versatility of side channel vacuum pumps makes them suitable for a wide range of applications across various industries. From vacuum packaging and material handling to medical suction and laboratory processes, these pumps play a crucial role in ensuring the efficiency and reliability of critical operations. Becker-International, a leading manufacturer of vacuum technology solutions, offers a comprehensive range of side channel vacuum pumps tailored to meet the diverse needs of its customers.

Choosing the Right Vacuum Pump

Selecting the appropriate vacuum pump for a specific application requires careful consideration of various factors, including vacuum level, flow rate, noise level, and maintenance requirements. By consulting with experts and leveraging the latest technological advancements, rotary vacuum pump businesses can optimize their processes and enhance productivity.

Maintenance and Care

Like any other piece of equipment, vacuum pumps require regular maintenance to ensure optimal performance and longevity. This includes routine inspection, lubrication, and replacement of worn-out parts. By adhering to a proactive maintenance schedule, companies can minimize downtime and avoid costly repairs.

Environmental Considerations

In an increasingly eco-conscious world, the environmental impact of industrial equipment cannot be overlooked. Dry vacuum pumps and oil-free variants offer significant advantages in terms of energy efficiency and environmental sustainability. By investing in these eco-friendly solutions, companies can reduce their carbon footprint and contribute to a greener future.

Future Trends in Vacuum Technology

As technology continues to evolve, so too will the field of vacuum technology. Advancements in materials science, automation, and digitalization are poised to revolutionize the way vacuum pumps are designed, manufactured, and utilized. Companies like Becker-International are at the forefront of these innovations, driving progress and pushing the boundaries of what’s possible in vacuum technology.

In conclusion, side channel vacuum pumps represent a paradigm shift in vacuum technology, offering unparalleled performance, efficiency, and versatility. Whether it’s in industrial manufacturing, healthcare, or research laboratories, these pumps play a vital role in powering critical processes and driving innovation forward. With companies like Becker-International leading the way, the future of vacuum technology looks brighter than ever before.