In the world of mechanical engineering and fluid dynamics, dump valves play a crucial role in managing pressure and ensuring the optimal functioning of various systems. But where exactly is a dump valve located? In this article, we will dive into the mechanics of dump valves, their significance, and their typical placements across different applications.

Dump valves, also known as blow-off valves or pressure relief valves, are devices used to release excess pressure from a system to prevent damage or malfunction. These valves are strategically placed in various systems to ensure the safe operation of equipment and machinery.

Understanding Dump Valves

Dump valves work on a simple principle: when pressure within a system surpasses a predetermined threshold, the valve opens, allowing a controlled release of fluid or gas. This prevents pressure from reaching dangerous levels and safeguards the system from potential ruptures.

Importance of Dump Valves

Dump valves play a critical role in maintaining system integrity. They protect against overpressure situations that could lead to catastrophic failures. By swiftly releasing excess pressure, these valves contribute to the overall safety and longevity of mechanical systems.

Dump Valve Locations

Dump Valve Placement in Steam Systems

In steam systems, dump valves are often situated at key points where pressure needs to be regulated. These include points close to steam generators and along distribution lines. The precise location depends on factors such as pipe layout, steam flow rates, and potential pressure build-up.

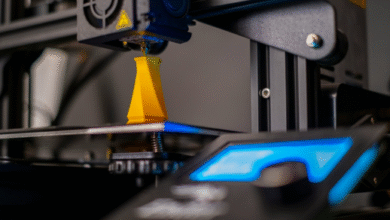

Dump Valves in Turbocharged Engines

Turbocharged engines utilize dump valves to manage the sudden pressure spikes that occur when the throttle is closed. These valves are usually positioned between the turbocharger’s compressor outlet and the engine’s intake manifold. Their strategic placement prevents damaging compressor surge and ensures smooth engine performance.

Dump Valves in Hydraulic Systems

Hydraulic systems benefit from dump valves placed near pumps or other pressure-generating components. These valves safeguard hydraulic lines and components from excessive pressure, maintaining the system’s efficiency and prolonging its lifespan.

Dump Valve Positioning in Industrial Settings

In industrial setups, dump valves are positioned within pipelines and equipment where pressure fluctuations are likely. Their placement is determined by system engineers who consider factors such as flow rates, pressure ratings, and potential impact on adjacent components.

Factors Influencing Dump Valve Placement

Several factors influence the placement of dump valves:

- Pressure Points: Valves are often located at points of pressure fluctuation.

- Flow Dynamics: Valve placement considers the flow path of fluids or gases.

- Equipment Layout: Positioning accounts for the overall layout of machinery and pipelines.

- Safety Concerns: Valves are placed in accessible areas for maintenance and inspection.

Installation Best Practices

Proper installation of dump valves is crucial for their effectiveness. Engineers must consider factors like sealing integrity, compatibility with the fluid or gas being handled, and proper orientation to ensure smooth operation.

Maintaining and Troubleshooting Dump Valve Locations

Regular maintenance is essential to keep dump valves in optimal condition. Inspection for leaks, proper sealing, and smooth valve movement should be part of routine maintenance practices. If a valve malfunctions, it’s important to diagnose and address the issue promptly to prevent system failures.

Dump Valves vs. Other Pressure Management Devices

Dump valves are often compared to other pressure-relief devices like safety valves and control valves. While safety valves are typically set to open fully at a specific pressure, dump valves provide a controlled release. Control valves, on the other hand, are used to modulate pressure within a system.

Dump Valves in Everyday Life

Beyond industrial applications, dump valves have found their way into everyday life. From home heating systems to household appliances, these valves contribute to the safety and efficiency of various products we use.

Dump valves are unsung heroes of pressure management, ensuring the safe and reliable operation of diverse systems. Their strategic placement, coupled with their efficient functionality, prevents disastrous pressure build-ups and maintains the integrity of mechanical setups.